Metal Inert-Gas And Metal Active-Gas Welding

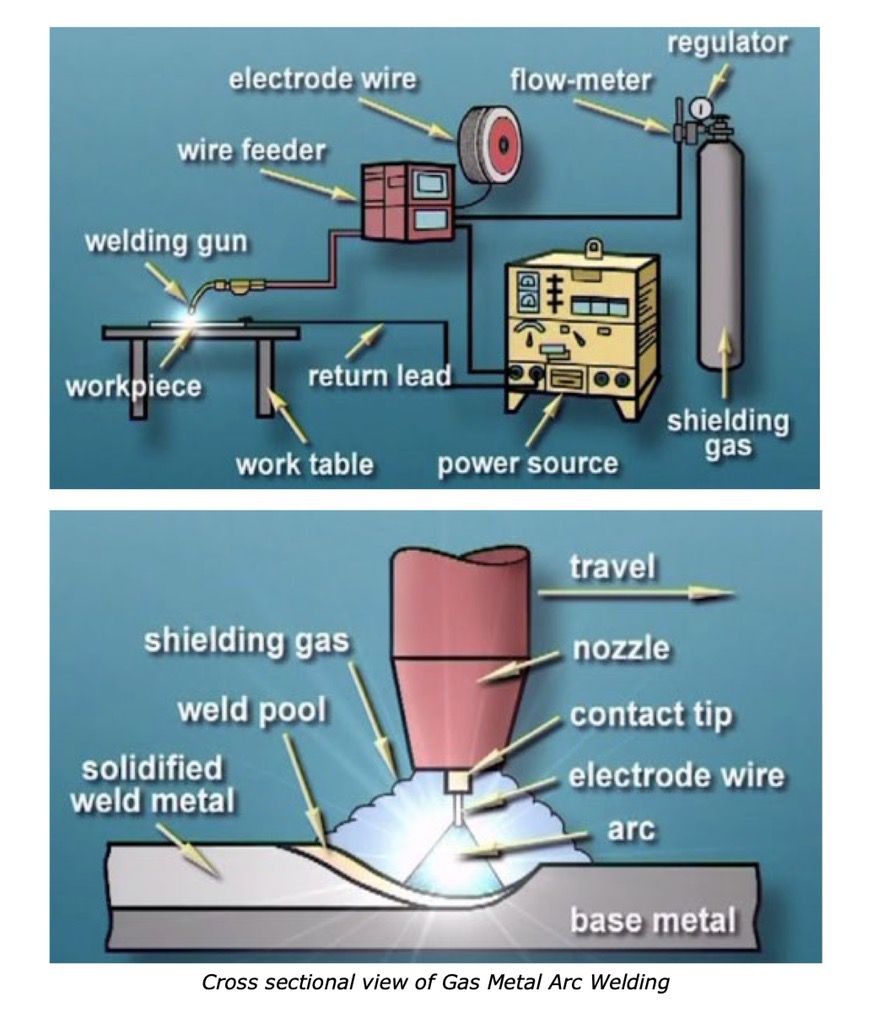

Metal Inert-Gas (MIG) and Metal Active-Gas (MAG) welding may be considered together because the welding equipment, including power source, is essentially the same. It is the shielding gas and consumables (filler wires) which differ.

*There are MIG/MAG processes which use a flux, either in the core of the wire or as a coating on the wire.

The MIG/MAG welding process uses a bare wire consumable electrode to provide the arc and weld metal. The wire, typically 0.8-1.6 mm diameter, is continuously fed from a coil through a specially designed welding gun.

Because the process is fluxless*, it is necessary to eliminate the possibility of atmospheric contamination by introducing a shielding gas. For some materials, argon is an efficient shielding gas, being inert, it does not chemically react with the weld metal. When an inert gas is used for shielding the welding process is known as Metal Inert-Gas (MIG) welding.

If a gas is inert it will not produce any reaction with another chemical. If a gas is active it is 90 capable of reacting with another chemical, e.g. CO2 is an active gas and it will react with iron, especially at high temperatures, to produce iron oxide.

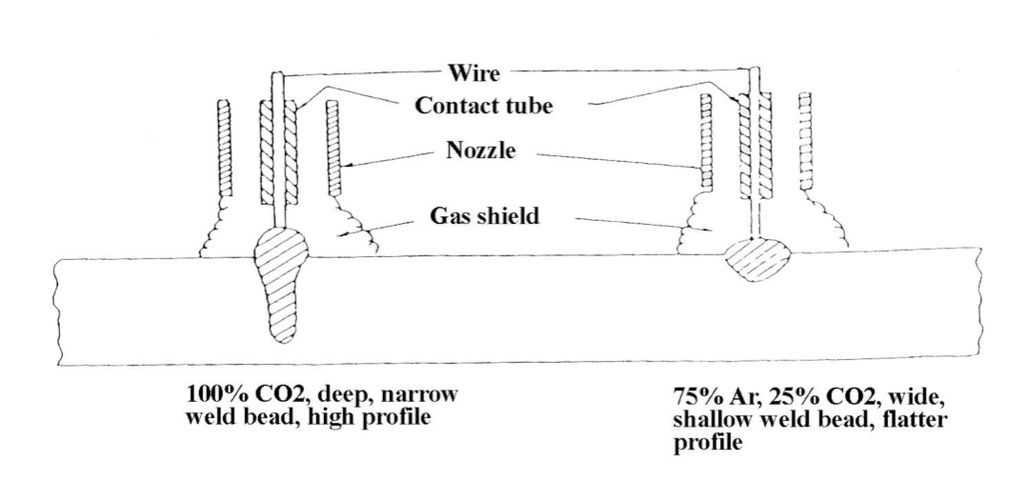

Different shielding gases change the electrical properties of the arc, this influences metal transfer properties, heat input, penetration and weld profile characteristics.

The shielding gas selected will depend on the material to be welded, the corresponding filler wire, and the required characteristics of the weld. For example, carbon steel–as an electrode–cannot be transferred successfully through a pure argon shielded arc; a very irregular weld profile with poor fusion would result.

Carbon steel can be transferred successfully through an arc using carbon dioxide (CO2) as the shielding gas. CO2 is an active gas, i.e. it chemically reacts with the weld pool to produce an oxide, and therefore extra deoxidizers must exist in the wire for an acceptable weld to be produced. This process is widely referred to as CO2 welding but is also called Metal Active-Gas (MAG) welding. This latter terminology also applies to the process when other active gases/gas mixtures are used, e.g. 75% argon, 25% CO2.

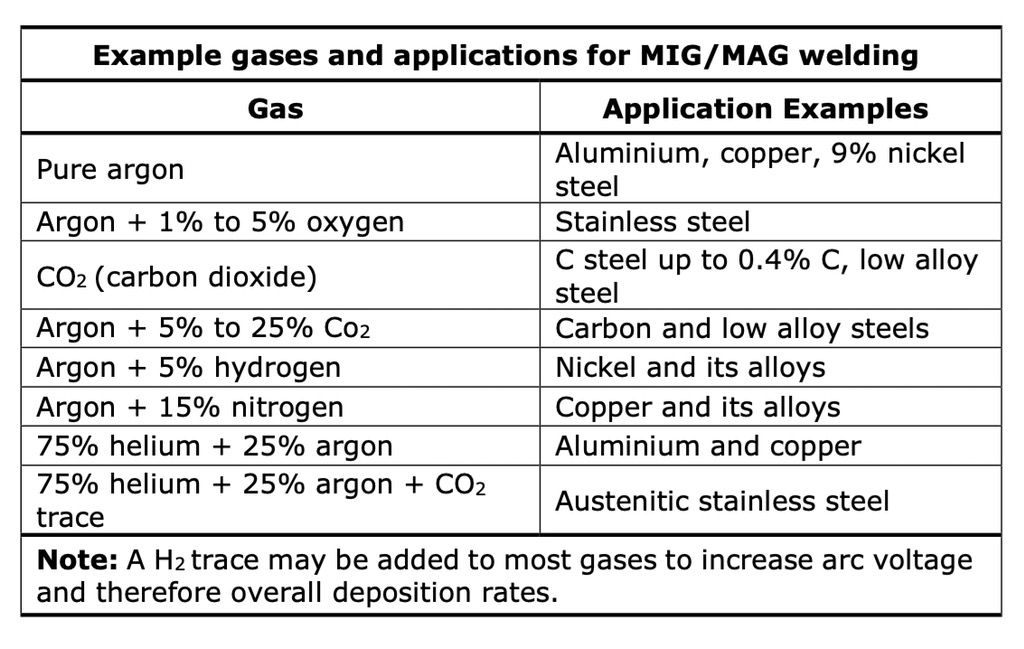

Shielding gases

The gas shield fulfils two main functions:

- it provides a suitable ionisable atmosphere for the electric arc,

- it protects the weld pool from atmospheric contamination.

Silicon is a primary deoxidizer. Manganese is a secondary deoxidizer.

A tertiary deoxidizer used in triple deoxidized wire is aluminium.

Wire consumable

The solid wire consumable used for MIG/MAG welding should conform to BS EN ISO 14341 Welding Consumables. Wire electrodes and deposits for gas shielded metal arc welding of non-alloy and fine grain steels or other agreed specification.

Because of the porosity problems which can occur when welding carbon steels with the MAG process, fully deoxidized (killed) wire, such as silicon manganese, should be used.

Metal transfer modes

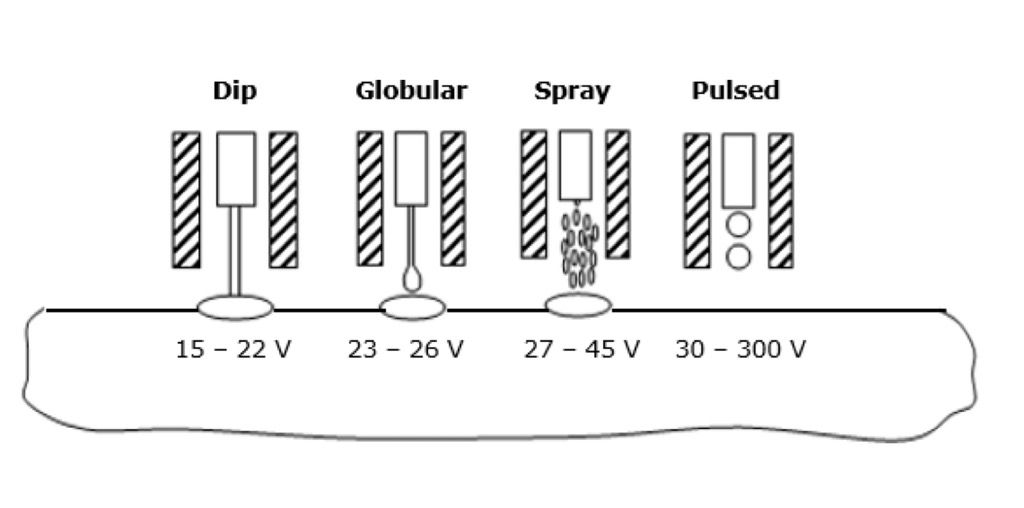

Metal transfer for MIG/MAG welding may be achieved in one of four ways:

- Spray or free flight transfer,

- Dip transfer (semi-short circuiting arc),

- Globular transfer,

- Pulsed transfer.

Types of Transfer

1. Dip transfer (semi-short circuiting arc or short arc)

To achieve dip transfer mode both low amperage and low arc volts are required so that the consumable wire electrode touches the weld pool and short circuits. This is followed by a short, rapid rise in current which causes the tip of the wire to melt off creating an arc which gradually reduces in length until it short circuits again and the process is repeated.

Because this transfer mode produces a relatively cool arc, it can be used on thinner sections and for all positional welding, including vertical down welding. Dip transfer would typically be used when welding a steel single vee joint open root with the MAG process.

2. Globular transfer (mixed arc)

Globular transfer mode occurs in the intermediate range between spray and dip transfer. This transfer mode has no manual application area in MIG/MAG welding and only limited success on mechanized and automatic set-ups. Globular transfer is unstable and leads to high levels of spatter.

3. Spray or free flight transfer

If a high welding current is used, the weld metal transfers across the arc in the form of a fine spray. This type of transfer gives high deposition rates and deep penetration welds. The spray transfer mode is suited to thick materials, and except for the light alloys may only be used in the flat or horizontal welding positions.

4. Pulsed transfer

Pulsed arc is a modified form of spray transfer which effectively uses both the dip and spray transfer modes in one operation. Pulsed transfer is considered to be the most effective and the most usual transfer used. Pulses of high powered spray transfer current are superimposed over a constant low semi-short circuiting background mode. This results in less heat compared to true spray transfer but is greater than with dip transfer; this permits hotter welding which allows for high deposition rates and all positional welding.

The main advantage of the pulsed transfer mode is that poor fusion of root runs is virtually eliminated. There is also regular penetration, no spatter, good profile, and the welds are of high quality.

Power requirements

Power for MIG/MAG welding is usually electrode DC +ve of a flat (constant voltage) characteristic, this can be obtained from a generator or transformer-rectifier.

Advantages and disadvantages

The advantages and disadvantages of the MIG/MAG welding process particularly when compared to MMA welding can be summarized as follows:

Advantages

- minimal wastage of consumable electrode

- no frequent changing of consumable electrode

- little or no interpass cleaning required (no slag produced),

- heavier weld beads are produced

- faster welding process

- low hydrogen process - preheat may not be required

- MIG is ideal for materials with high oxidation rates i.e. Magnesium, Titanium and Aluminum.

Disadvantages

- increased risk of porosity - due to displacement of the gas shield,

- more maintenance of plant involved,

- high risk of lack of fusion,